Avibulb

High Strength Riveting Solutions by MIS

At MIS TOOLS BUILDING METAL PRODUCTS TRADING LLC, we are happy to offer the Avibulb Rivet— a high-strength rivet solution that has been engineered to provide stringent performance requirements within thin sheet material. From uses in the automotive and electronics industries through to markets including enclosures, the Avibulb Rivet offers a guaranteed and durable join regardless of harsh environmental exposures.

What Is an Avibulb Rivet?

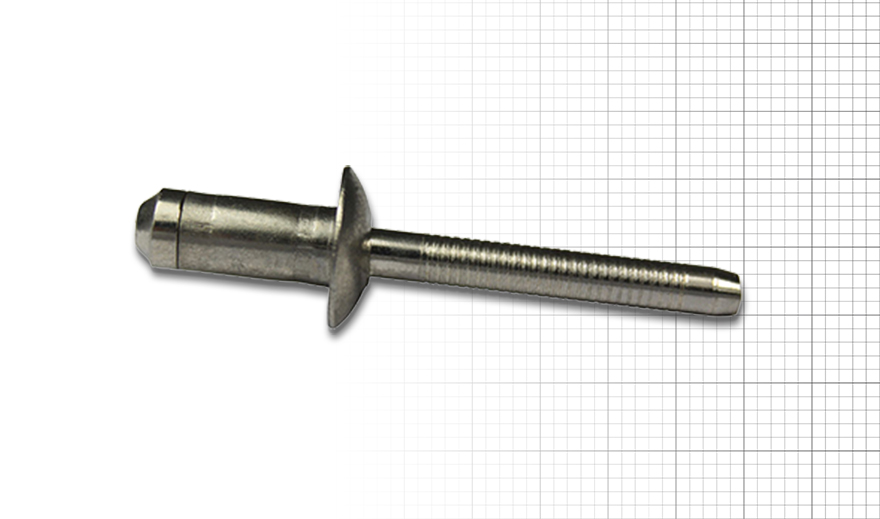

Avibulb Rivet is a bulbing-type structural blind rivet that works best in tensile-strength and high-shear applications. It creates a wide, bulbed tail in the blind position when installed, spreading load over a larger area, and performs best on applications where softer or thinner material is encountered.

Additionally, Avibulb Rivets also feature a retained stem, which provides vibrational resistance, rattling, and electrical issues from loose internal components. It’s an added benefit in precision-high and safety-critical applications.

Avibulb Rivets Key Features

- Heavy-duty shear and tensile strength for heavy-structure applications

- Bulb tail formation for even distribution of load on the blind side

- Superb hole fill for safe fitting in oversized or non-uniform holes

- Retained stem design for vibration resistance and long-term reliability

- Large blind-side bearing surface that protects thin material from stress

- Prevents movement in non-standard holes or rough surfaces

- Electrically safe construction with no loose metal parts

These features make the Avibulb Rivet appropriate for the achievement of structural integrity and precision in assembly processes.

Applications of Avibulb Rivets

Owing to their unique engineering, Avibulb Rivets are widely used in industries:

Automotive: For vehicle chassis, body panels, and load-carrying joints

Electronics: In sensitive assemblies requiring insulation and stability

Cabinets and Enclosures: With clean finishes and secure holds

Construction & Frames: For rigid, vibration-free fastening

Specialty Applications: Also in Earth Tab (zinc-plated steel with brass earthing tab) for electrical grounding applications

Sizes and Materials Available

Size: 6.4 mm in diameter to suit various grip thicknesses.

Materials: Steel, zinc-coated, and clear passivated finishes

Headform: Dome head for an architecturally clean appearance

Recommended Tools

For the ultimate installation experience, MIS suggests tools, which are:

These tools offer efficient and repeatable performance, and they are ideal for a production environment.

Installation Benefits

Avibulb Rivets consist of several advantageous features for installation. Simple and quick installation conserves access time to both sides of the material, thus they are ideally used where reverse access is restricted. They also gain high compatibility with automated equipment, which provides them with constant performance in the assembly line. The design also promises less downtime as there’s minimal possibility of tool jamming or operator error while being installed.

Industry Standards and Compliance

MIS ensures that all Avibulb rivets are ISO and DIN-compliant, validating their application in safety-critical applications. They also possess environment-friendly finishes such as zinc and passivated coatings, which not only comply with the industrial standards but also contribute to corrosion protection and operating safety.

Environmental Resistance

Engineered to withstand harsh environments, Avibulb Rivets are corrosion-resistant, withstanding humid, marine, or chemically exposed environments. They are also temperature-resistant, maintaining their integrity and performance on high and low-temperature operations.